Ballast Control System on Ships and FPSOs

Manufacturer: Honeywell Marine

FLUXO Soluções Integrados, together with its partners, Honeywell Marine and Skarpenord AS, provide the Brazilian market with the Complete Solution for the Cargo Monitoring System and Remote Valve Control System for all types of vessels in the FPSO and bulk carrier market .

THE Honeywell Marine, through its Enraf division, specializes in providing monitoring systems for cargo and ballast tanks for ships and FPSOs.

THE Skarpenord AS is a Norwegian company of the Scana group, manufacturer of remotely actuated valve control system for ship hulls, with supplies also for oil tankers, including those from Brazilian fleets.

FLUXO, which represents and distributes the systems of both companies in the Brazilian market, conceived the convergence of their supplies through a single package.

Honeywell Marine

Complete solutions for measuring operations in cargo tanks, ballast and service tanks. It also includes temperature and pressure monitoring of inert gas, performs correction calculations and brings innovations in the field of human-machine interface (HMI).

Our main portfolio comprises:

Tank level measurement solution

Integrated system for measuring level, temperature and pressure for cargo, ballast and service tanks.

Ballast Measurement and Service Tank

Common standard for measuring ballast and service tanks. Several technologies for different applications: Electropneumatic, Pressure, Capacitive, Guided Wave Radars.

Extremely reliable solutions used to ensure ship stability, environmental protection and reduced fuel consumption.

LIDEC

Liquid level switch designed for marine use;

An effective solution to detect liquid level. Equipped with one or two modular probes, it is a fully static device using surface wave propagation. The detector is insensitive to vibration, shock and electrical disturbances.

Pressure and level sensors

The PL3700X is a family of pressure sensors that meet many of the pressure and level sensing needs aboard a ship. They come in a variety of detection ranges, materials, fitting types and accessories.

The PL3700 can be immersed into the tank using an adapted bracket or mounted on the side using a flange.

Capacitive Level Sensors

OptiLevel is the best choice in small tanks for barges, marine and shipping vessels. Based on capacitive sensing technology, it provides charge level, oil and water interface level and temperature measurement in an independent sensor with no moving parts.

Electropneumatic Transmitters

CT801: Remote Level Measurements Based on the Bubbling Principle

providing 4-20 mA analog output.

The transmitter's proven reliability has made it the marine industry standard for equipment in this category, with more than 2,000 vessels already equipped.

Cargo tank high level alarm and overfill protection

The CARLA System is a fully autonomous solution, which meets the standards of protection against accidental overflow of the cargo tank.

Its main advantage is the use of the Honeywell Lidec L91 (single probe) or L92 (dual probe) as two independent level alarms.

Communication and Security Units

The TA3840C communication unit is based on a monitoring and charging system.

The TA3840C calculates and displays parameters such as charge level, temperature and pressure.

The unit can be installed in a 19-inch rack and includes a power board, central unit board for data processing, function keypad and LCD display unit for measurement and alarm data, with up to four communication ports and up to 96 analog inputs.

Electropneumatic cabinet

The TN3801 is ideal for service, ballast and draft tanks.

It can include up to 24 channels of independent pneumatic modules. Modules are integrated with an automatic check valve. Inside the TN3801 a microcontroller performs data processing,

digital conversion and management of two redundant RS485 / 422 communication ports.

CargoBoss Tank Measurement Software

User-friendly software that can run on a PC. CargoBoss captures critical data related to net cargo, ballast and service tanks, such as level, pressure, temperature, empty volume, corrected volume, mass and ballast level data in real-time from the TA3840 communication rack. This also aggregates other information such as cut, jump and GPS data. The CargoBoss then provides an accurate view of this data using an intuitive human-machine interface (HMI) and communicates it via RS-485 Modbus to the cargo computer and vessel system.

An optional GSM modem allows communication of all this data, including GPS position, tank levels and other parameters, to a remote FTP location for use by the owner, oil company or charterer.

Skarpenord

Our main portfolio comprises:

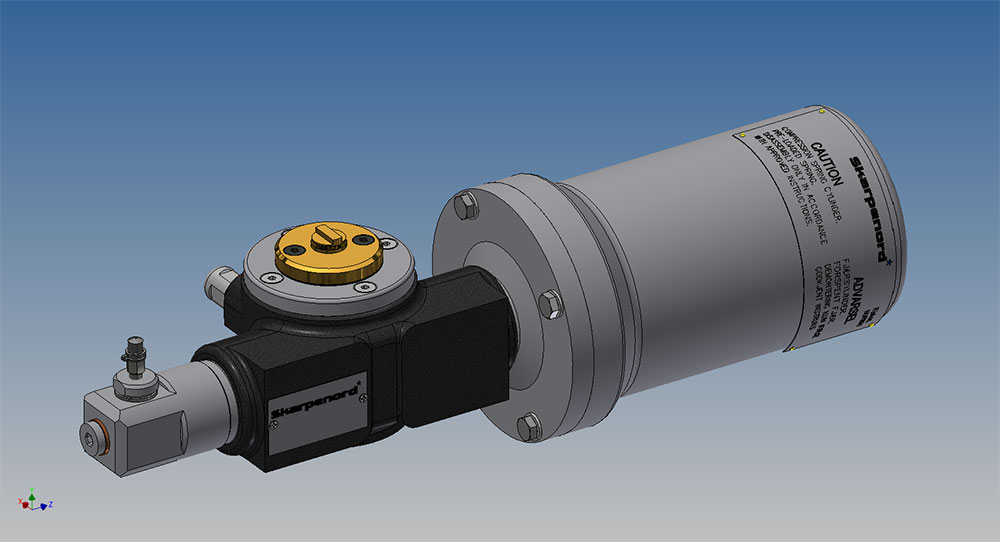

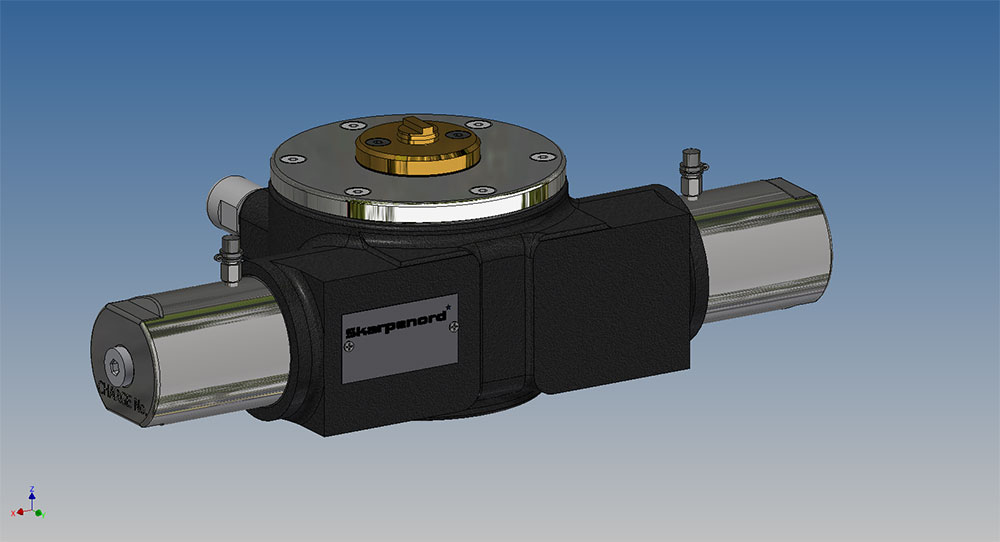

Hydraulic Actuators

Skarpenord hydraulic actuators can be supplied as single acting or double acting and can operate all types of ball and butterfly valves. The design simplifies maintenance and installation, which offers the customer a low-cost product. Quarter-turn actuators are provided with adjustable stroke or fixed 90-degree rotation with mechanical locking

Solenoid valve cabinet

The cabinet contains solenoid operated directional valves for delivering high pressure oil to the actuators. Valve position can be measured indirectly and transferred to the Skarpenord computerized valve control via a single cable unit.

HPU Hydraulic Power Unit

The hydraulic power unit with oil reservoir, hydraulic pumps and accumulator unit supplies the system with high pressure oil.

All components are selected to ensure high reliability and low noise.

Computerized Valve Control

Skarpenord computerized valve control is a centralized system for controlling / monitoring valves and hydraulic unit. Operation is performed on touchscreen or trackball / keyboard. The solution minimizes the need for cabling between different units.

The control station (PC), logic controller (PLC) and operation panel on the SVC are interconnected by a bus cable. This will simplify the installation work. All control components are produced by renowned companies with worldwide technical support.

Related articles

- Flux, Scana and Honeywell Enraf together to provide VRC and Ballasting systems for FPSOs

- Scana is the new partner for remote control of vessel valves

- Prospects for market recovery lead to Fluxo to Rio Oil & Gas 2018