Faure Herman Helical Meter gains prominence in Brazilian terminals

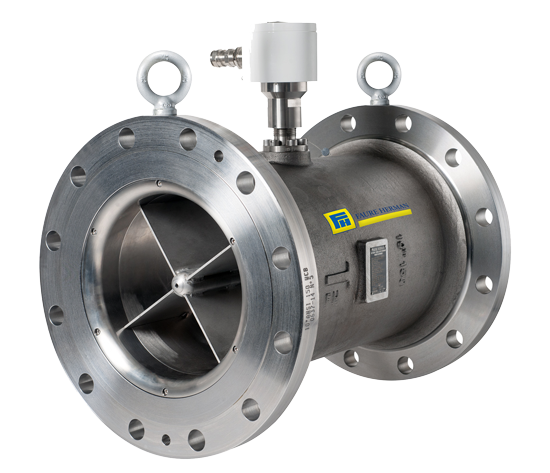

The Helical Meter manufactured by Faure Herman and distributed exclusively by FLUXO in Brazil for the onshore market has become the preferred choice of users seeking high precision and low uncertainty in the measurement of fluids in liquid bulk loading terminals. Whether loading tank trucks and train cars or unloading, this meter has proven to be extremely repeatable and reliable.

Faure Herman, founded in 1925 and headquartered in La Ferté Bernard, France, specializes in the manufacture of Helical flowmeters. Its equipment is recognized worldwide for its high performance and robustness, including being used for oil measurement on platforms (FPSOs) with several operational units at Petrobras and on chartered vessels in Brazil.

The high performance of the Helical Meter is achieved by means of a specially machined Helical Rotor, which allows precise measurements in a wide range of viscosity. Unlike conventional turbine meters provided by other manufacturers, the Helical Rotor is more resistant to warping and unbalance caused by impurities that may pass through the filter.

The fluid velocity is parallel to the meter blade, making it less sensitive to viscosity and density variations. Its helical shape and rounded front edge, combined with lightweight materials, improve measurement stability and linearity, even in highly viscous fluids, reducing wear on bearings.

It is worth mentioning that the 3” and 4” model TLM meters do not require a Straight Section upstream and downstream, which makes it different from other turbine-type meters available on the market.

Because they are much more stable than conventional meters, which use vane-type rotors, the calibration factor of the Helical Meter practically does not change during calibrations, which allows reducing the frequency of these calibrations, reducing the cost of OPEX.

In Brazil, several companies already use these meters, including Ipiranga and Ultracargo, which have 170 units installed. For Ultracargo, for example, 72 meters supplied for rail loading at the Terminal in Itaqui have been in operation for over 4 years with excellent performance, 18 of which measure biodiesel (B-100).

For biodiesel lines (B-100) that are used for mixing with diesel, 2" meters of the TZN model are used. These meters have an extremely robust titanium rotor and are suitable for measuring biodiesel (B-100) .

It is important to note that all meters are calibrated in the Faure Herman reference laboratory, which is accredited by COFRAC in accordance with the ISO/IEC 17025 standard and is a member of the ILAC (International Laboratory Accreditation Cooperation).

These calibrations are carried out under process conditions similar to those existing in the terminal, facilitating the calibration carried out in the field, in addition to ensuring the best performance of the meters that will be supplied.

An important point is that, although the arrow is still widely adopted as a reference in measuring the loading of tank trucks and train wagons, the TZN model meters have the PAM (Model Approval Ordinance), which is another relevant differential of this model. , as its performance is validated and attested by INMETRO itself.

A great advantage for the maintenance team is that the two main spare parts, Pick-up Coil and Pre-Amplifier, used in the 2" meter for the B-100 lines and for the 3" meters for the other fluids are the themselves, greatly simplifying the spare parts that the terminal must keep as a reserve for eventual replacements.

Another peculiar feature of the TLM model meter is the ability to operate with particles of up to 1mm, using a filter upstream of the meter with at least 18 MESH. The 2” TZN model meters are capable of operating with particles of up to 0.85mm, with the use of a filter upstream of the meter with at least 20 MESH.