Innovation for terminals: automated vegetable oil loading and measuring system

In 2023, Cattalini Terminais Marítimos invested in its vegetable oil loading, through an innovative skid with a selection of three different products, automated temperature control and integration with the terminal's control systems. The focus on the movement and measurement of vegetable oil was maintained, highlighting the economic and operational safety benefits that these technologies provide.

In this specific scenario, FLUXO was chosen to develop, manufacture, install and put into operation a Turn-Key project, one of FLUXO's expertise.

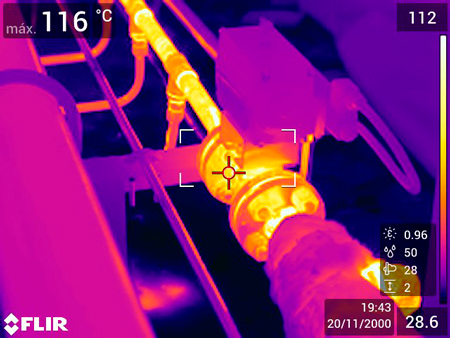

Therefore, we searched the market for a heating system specifically designed to optimize the movement and measurement of vegetable oil. The guarantee of heating homogeneity dedicated to measurement control was the main point of the specifications.

Efficient movement of vegetable oil presents unique challenges, with temperature control being one of the critical factors. Oil viscosity is directly affected by temperature, making an accurate and effective heating system essential. In this context, our new system appears as the ideal answer to overcome these challenges, providing a smoother and more controlled process. We can apply this same system to loading asphalt, heavy fuel oils and other viscous products.

As in every measurement system, the flow meter is a fundamental piece in this Skid equation. Therefore, FLUXO selected Yokogawa's Coriolis Flow meter, providing accurate and consistent measurements. Its technology based on the Coriolis principle offers a significant advantage in the measurement of viscous fluids such as vegetable oil, guaranteeing reliable results even in the challenging conditions that terminals that move heated fluids have.

Yokogawa Rotamass Total Insight (TI) Coriolis mass flowmeter provides high accuracy in measuring liquids while adopting the Total Insight Concept. It also features the Total Health Check advanced diagnostic system, which makes it easy to determine the condition of the flow meter without interrupting measurements and recording information.

The flow pre-determiner is responsible for all operational control of the fluid transaction. In this process, recipes are automatically read by Fusion4, allowing the heating system to adjust temperatures precisely, ensuring a smooth transition between different products.

By using this loading skid, Cattalini was able to eliminate unnecessary truck weighing check procedures. Our new heated vegetable oil loading system represents a significant milestone in the evolution of the terminal sector, offering not only an efficient solution, but also contributing to the operational safety and reliability of the loaded product. By investing in this innovation, companies like Cattalini can not only improve their operational efficiency, but also position themselves as protagonists in the search for more conscious practices. Together, we are shaping the future of the terminal industry.