Electronic Preset (Preset)

Fusion4 Electronic Predeterminator

Manufacturing: Guidant Measurement

The Fusion4 Preset is the most advanced solution on the market for controlling loading at fuel and industrial liquid distribution bases. Designed for demanding environments, it combines metrological precision, ease of operation, and operational robustness, ensuring reliability in every transaction.

How it works

Fusion4 acts as a loading controller (preset), precisely managing product flow, additive dosage, and loading arm control. Its modular system allows up to six arms to operate simultaneously with additive injection and blending. With an intuitive icon-based interface, the equipment reduces operational errors and optimizes operational performance.

applications

- Road, rail and sea loading terminals

- Fuel distribution bases

- Operations with additive injection and simultaneous blending

- Custody transfer units

Fusion4 Portfolio

Guidant's Fusion4 line offers a complete and scalable portfolio for terminal loading, blending, and additive injection applications:

- Fusion4 MSC-L: Advanced multi-flow controller capable of operating up to 6 loading arms simultaneously, with integrated mixing and additives. Ideal for metrologically accurate loading control.

- Fusion4 MSC-A: High-capacity multi-stream controller designed to independently control up to 24 additive injection streams. Highly recommended for applications requiring multiple additive lines.

- Fusion4 SSC: Single flow controller with dedicated software for precision mixing and additive injection. Suitable for specific operations and applications with a single arm or line.

- Fusion4 MiniPak: combines the SSC with the Mono-Block injector in a compact and precise solution for single-line additive injection.

- Fusion4 MultiPak: integrates the MSC-A with multiple Mono-Block injectors into a complete additive injection skid, ready for installation in highly complex applications.

Technical specifications

- Integration with Mono-Block and other additive injectors

- Compatible with Modbus protocols (TCP/IP or RTU)

- Multilingual support

- Configurable inputs/outputs

- Quick installation with calibration wizard

Main features and differentials

- Can control from simultaneously forms up to 6 independent loading arms and 24 flow meters, with their respective in-line mixtures, additives and marking

- Excellent I/O capacity, allowing control of future demands, as occurred in the past, with the need to control additives, markers and the blending of biodiesel into diesel

- Configurable I/Os: association of any function to any input or output (I/O)

- Modular design that allows future expansion of I/O's, which can increase the capacity of arms to be controlled

- Firmware updates performed in the field via Local Access Device (LAD) that uses an SD card and is certified for use in hazardous areas, without the need for a computer in the field. It is the only preset on the market that has this function.

- Intuitive interface in Portuguese with icons on an 8” WVGA color display that eliminates the need for special training for operators

- Advanced alarm management: monitors twice as many parameters as other models

- Real-time diagnostics: dashboard for quick problem identification

- Interface with Terminal Management Software (TAS) over Modbus TCP for fully automated terminal control

- Non-volatile memory recording of up to 10,000 transactions and 100 calibration records

- Identifies the driver and stores vehicle data input, product scheduling, recipes and loading control in a simple and secure way

- It can be supplied with two power supplies, thus maintaining operation even if one of the sources burns out.

Advantages of Preset Fusion4

- Metrological accuracy: ideal for custody applications

- Intuitive interface: reduces training time and risk of errors

- Modularity: scalable according to the complexity of the operation

- Full integration: compatible with injectors and legacy systems

- High visibility: complete real-time monitoring

- Lower operating costs: fast updates and simplified maintenance

Certifications and compliance

- INMETRO approval for use in classified areas

- Model Approval Ordinance (PAM), Inmetro/Dimel No. 107, issued on June 14, 2019

- MID (EU) and NTEP (US) compliance for custody applications

- Supports full traceability with calibration, event, and transaction logs

- Compatible with Fusion4 LAD for data transfer in hazardous areas

- Certification of firmware and real-time diagnosis

Related articles

- Electronic preset Honeywell/Enraf Fusion4 MSC-L is approved by Inmetro

- Electronic preset Honeywell Fusion4 became the favorite of terminals in Brazil

- Cattalini expands loading capacity with yet another Flow automation solution

- Ultracargo automates Fluxo's rail loading system with skids

- Cattalini will further modernize its rail loading with an automated Flow system

- Parnaíba Gás Natural starts production of Gavião Branco with Fluxo systems

- Cattalini invests in Fluxo's technology to optimize its processes

Contact

For more information about Preset Fusion4 and other terminal automation solutions, please contact [email protected].

MicroLoad Electronic Predeterminator

Manufacturing: Guidant Measurement, Smith Meter® brand

The Preset MicroLoad is a compact and robust electronic controller designed for precise liquid loading control in single-meter applications. Versatile, safe, and compatible with international measurement standards, the device is ideal for integration with automation or operation systems. stand-alone at loading terminals.

How it works

The MicroLoad precisely monitors and controls the volume, temperature, pressure, and density of liquid products in a single metering line/loading arm. This compact presetter automatically corrects based on real-time data, ensuring the delivery of volumes in compliance with ASTM and API standards. It can operate independently or be integrated with SCADA systems, PLCs, and automation platforms via serial or Ethernet communication. The equipment also supports sampler control, with configurable frequency by time or volume, as well as the use of smart additives.

applications

- Loading of fuels and chemicals

- Real-time additive and sampling control

- Installations where simplicity, safety and precision are essential

Technical specifications

- Automatic temperature correction (ASTM D-1250 and API MPMS 11.1)

- Pressure compensation (API 11.2.1 and 11.2.2)

- Density correction (via 4-20 mA input or AGA-8 calculation)

- Simultaneous control of up to 4 additive injectors

- Communication via 10/100 Base-T Ethernet (RJ-45) and 3 serial ports (EIA-232 or EIA-485)

- Support for Modbus RTU and Smith Meter ASCII protocols

- Boolean and algebraic processing for custom logic

- Print sharing between multiple units

- Operating range: -25°C to +60°C (IP65 / NEMA 4X)

- Power: 115/230 VAC, 50/60 Hz, 9W consumption

Advantages of Preset MicroLoad

- High precision: compensations according to ASTM/API standards

- Easy integration: with automation systems and additive injectors

- Flexibility: configuration of inputs and outputs for total customization

- Operational safety: double pulse checking and automatic alarms

- Simplified operation: user-friendly interface and configurable reports

- Reliability: Display with OIML option keeps data visible for up to 15 minutes after a power outage

- Compact and robust: installation in classified areas with minimal infrastructure

Certifications and compliance

- Hazardous Area Approvals: INMETRO / UL Brazil, UL/CUL Listed, ATEX (DEMKO 04 ATEX 0403315X), IECEx (UL 04.0007X)

- Protection rating: NEMA 7 (IP65)

- EU Directives: Compliant with the European Union EMC Directive (EN 61326-1)

- Measurement standards: Complies with API MPMS, ASTM and OIML standards

Contact

For more information about Preset MicroLoad (microFlow.net) and solutions for automating liquid loading and metering, please contact [email protected].

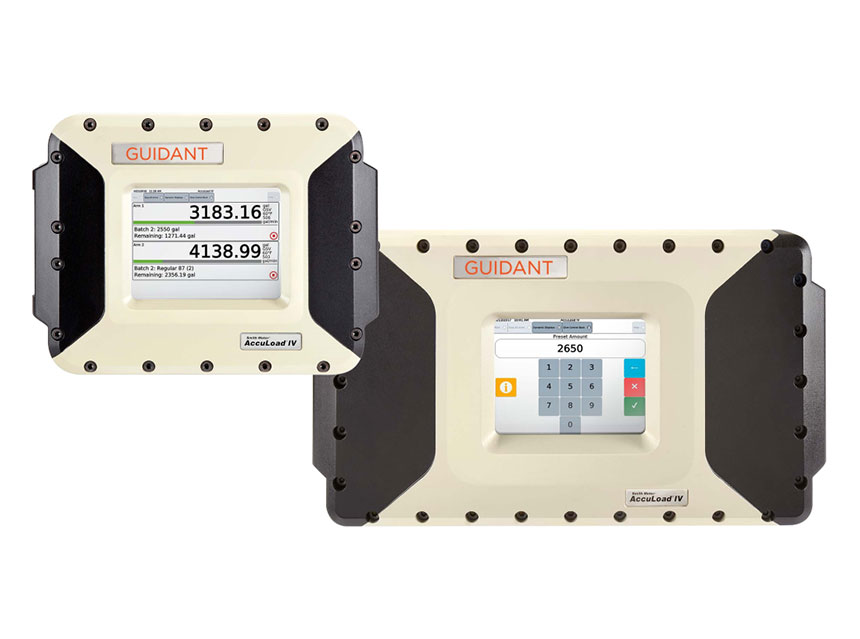

AccuLoad IV Electronic Predeterminator

Manufacturing: Guidant Measurement, Smith Meter® brand

The AccuLoad IV Preset is the latest generation of Smith Meter® Electronic Presetters. Available in ST (Single Touch Screen) and QT (Quad Touch Screen), the AccuLoad IV combines powerful processing, Ethernet connectivity, safety in hazardous areas and easy integration with automation systems.

How it works

The AccuLoad IV utilizes a completely new hardware and software platform, with a powerful Linux operating system and an intuitive touchscreen interface. The system allows for individual configuration of loading arm functions, such as pure product delivery, sequential and ratio blending, and unloading operations. With its Split Architecture system, it can control and monitor up to 18 loading arms and 24 meters.

applications

- Custody transfer in loading and unloading of liquid petroleum products

- Batch loading of biofuels, gasoline and diesel oil

- Loading tanker trucks, rail cars or barges at terminals, distribution bases and docks

Technical specifications

AccuLoad IV – ST (Single Touch Screen)

- Control of up to 2 simultaneous loading arms, with mixture, with up to 4 meters

- Simultaneous control of up to 4 additive injectors

- Simultaneous control of up to 24 additive injectors with the A4I Module

- 8.4" touchscreen interface (front HMI)

- Support for analog, digital, temperature and pulse inputs

- Simple installation with reuse of existing cabling (in upgrades)

- Suitable for use in classified areas

- Kit (UG3) available to upgrade from Accuload III to Accuload IV

AccuLoad IV – QT (Quad Terminal)

- Control of up to 6 simultaneous loading arms, with up to 3 mixes and 6 meters

- Module A4M + Module A4B (input/output expansion)

- Simultaneous control of up to 4 additive injectors

- Simultaneous control of up to 24 additive injectors with the A4I Module

- 8.4" touchscreen interface (front HMI)

- Support for analog, digital, temperature and pulse inputs

- Simple installation with reuse of existing cabling (in upgrades)

- Suitable for use in classified areas

- Kit (UG3) available to upgrade from Accuload III to Accuload IV

- Ideal for large bases with multiple simultaneous loads

Common to both versions

- Ethernet connectivity (4 RJ-45 ports), with communication between modules and integration with external network

- Compatible with Modbus and Smith ASCII protocols

- Operation in classified areas

- Ambient temperature: -25°C to +60°C

Advantages of AccuLoad IV

- Modular and expandable architecture: adapts to different sizes and complexities

- Legacy-compatible: Easy upgrade from AccuLoad III

- Touchscreen display with intuitive interface: direct operation in the field

- Robust Ethernet communication: integration with supervisory and automation systems

- High accuracy and reliability: ideal for custody transfer applications

- Simplified maintenance: module replacement without rewiring

Certifications and compliance

- Hazardous Area Approvals: INMETRO / UL Brazil, (NEMA 4X, IP65), ATEX, IECEx, UL / CUL

- Compliance with international standards: API MPMS and ASTM standards for volume corrections

Contact

For more information about the Preset AccuLoad IV and other terminal automation solutions, contact [email protected].