Petrobras acquires TapcoEnpro slide valves for Regap's Catalytic Cracking Unit

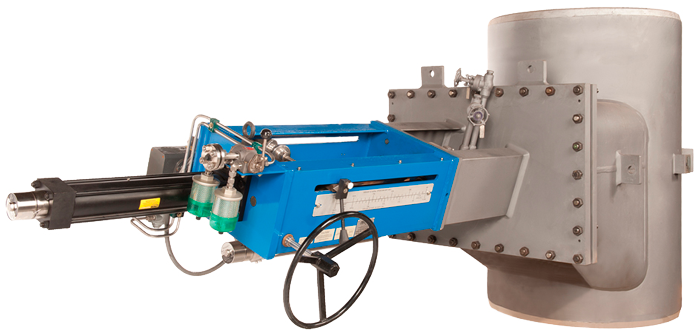

In partnership with the represented TapcoEnpro, FLUXO will supply another two type S valvesdeal for application in regenerated catalyst at the Catalytic Cracking Plant (FCCU) at the Gabriel Passos Refinery, (Regap).

This supply includes valves Cold Shell Design, body manufactured with cold laminated boards, according to Petrobras and licenser’s project specifications. The most recent computing design techniques are applied for the manufacturing of sliding cylindrical body valves with a set of “set on” rectangular bonnet with rounded corner. This design bears thermal expansion in elevated temperatures.

The valve internal components are manufactured with accurate dimensions, which ensures reliable operations in elevated temperatures, under extreme conditions. All internal components are accessible “through the bonnet” to facilitate maintenance.

Cold Shell valves require that the valve inlet port, bonnet and valve outlet be completely covered with a single layer vibrating insulating refractory lining over a V-anchor system.

TapcoEnpro slide valves are developed to overcome the industry standards regarding safety, performance, and reliability for installation of processing, enabling the factories to safely operate without non-planned downtimes.

TapcoEnpro has a significant installed premise in Brazil, with equipment at Regap, Replan, RPBC, Revap, Repar, Refap, and Reman. FLUXO is responsible for post-sales and local technical assistance.